The BLOG is discontinued !! - below is the contents of how it looked (-ish) at the end.

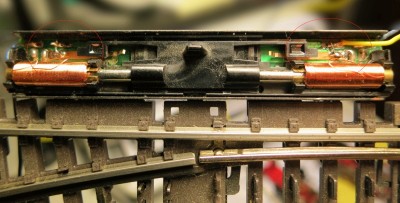

K-Track ! - some tournouts can be unrelaible, and not shift very well.

The reason is a small toung which gets liftet when the shifter moves to

one end, and this breakes the electrical connection and the shifter looses

its momemtum

and may not shift at all.Its made to prevent the coils from burning out

if someone where to hold the shift button down forever on an older analog

switch.

In digital the power gets cut after normal 200ms but in that time it may

not have shiftet at all.

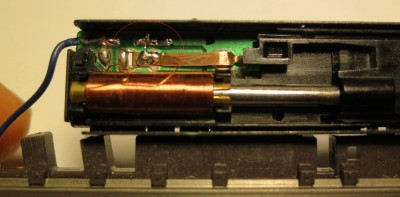

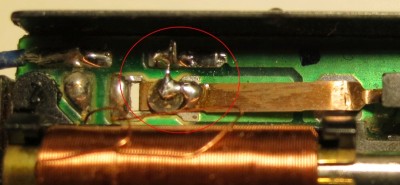

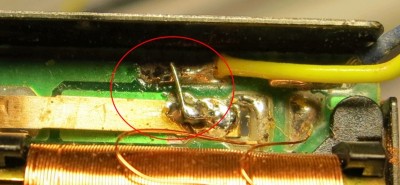

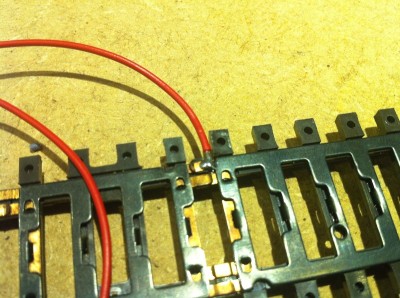

The solution is to solder 2 very small wires to short out the tounges, so

they wont cut the power.

Be aware if you are shifting the old fasion way with contact box'es, there

will now be a risk of frying the coils if its powered for too long a time.

Solder the wires as seen on the pictures.

Soldering feeder wires to Märklin K-Tracks does not need to be difficult.

Solder the red wire to the small tounges under the track. Be carefull and

use as little solder as possible, so you dont solder the tounges together.

Its also a good idea to solder in the small recess next to the black metal,

so the wire fits nicely beneath the track.

Solder the brown wire to the rails, by soldering it to the railjoiners.

Again - dont use to much solder, as it may cause a shortcircuit.

Sorry for the somewhat blury pictures.

I just bought 2 Loko's which where sold as defective.

One was a BR52 (3415), which was "running wobbly" and the other

was a BR E91 (3628),which where suposed to be electricly defective.

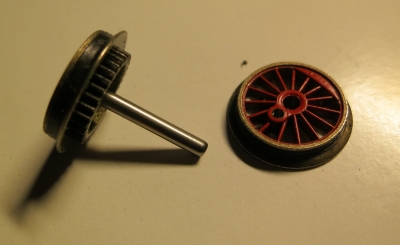

It turned out the BOTH loko's have at some point had their wheels removed

at put back on again.

But unlees you know what you are doing this can lead to big problems, and

with my 2 loko's it certainly did.

Both loko's had wheels so loose that you could ealisly remove them with

your fingers.

The only true way to get them back on firmly is to “knurl” the

axles. Any type of knurlig will work as long as it adds to the overall thickness

of the axle.

See how smooth the axle was on my BR52 – that would never grab on to

the wheel.

Of course you need to rough up the axles evenly all the way around, or the

whell will not sit center on the axle and the lok will run wobbly again

If you are unlycky, the hole in the wheel has become so large from all slipping,

that not even knurling will make it grab the wheel firmly – then you

need to get a new wheel.

I did not have the possibility to knurl the axles, so I mailed them to a

friend which did a good job. Here you see the result.

Now all I have to do is press the wheel back on. To that I will be using

a small vise, and take care that I press evenly on the whole wheel or at

least evenly on the rims.

Also remember, if your lok’s have tie rods, the the wheels must be

set at an angle of 90 degrees from each other.

The distance between the inside of the wheels should be 13,8mm for Märklin

AC.

What have I learned from this….

People who remove wheels and dont know what they are doing, are fools !!!

– And, dont buy loko’s with loose wheels unless you have the tools

to fix it.

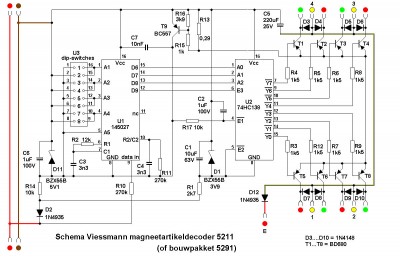

I just compared a new and an old 5211, and here are some observations.

The box is the same exept the new one can be hanged in display stands

(in the store).

The old could as well, but a flap had to folded up leaving a hole in the

box.

Paper inside box (users manual) was printed professional on glitted paper,

now it seems printed on a standard laser printer.

Its also still primarilyin german, and it would (again) have been nice if

it was printed in color.

New 5211 it self is printed now only with black - no colors. The old one where in colors which made it easier to use.

The new 5211 now uses a lot of SMD components, which has made the circuit

board much nicer to look at – not as “messy” as before.

They still use some “through-hole” components such as capacitors,

big resistors and the main chip MC45027.

The new works as great as the first, but its clear that cutting costs have made the product seem a bit less quality.

ohh, and btw, they still uses those plastic plugs where you threads the

wire through.

I dont like them very much, since they some times pop out and they also

limit the thickness off the used wire. I use Märklins old plugs with

a screw – they work great.

The 5211 can be modified to switch more reliable.

The capacitor C5 of 220uF can be enlarged – but not too big though,

else it will take to long to charge it. I chose another 220uF/25V.

Also if it bacame much bigger it would not fit inside the 5211 box. Just

solder it parallel to the existing capacitor – positive to positive

and negative to negative.

P.S The schematic is of the old 5211 with descrete components. The new are

with more SMD components and I have heard its slightly different (but not

much – an extra diode and such)